MIG or (GMAW) is one of the most popular welding processes. Metal inert gas (MIG) welding joins together two pieces of metal, using an electrical supply to fuse the base metal with a consumable electrode filler. The process can be semi-automatic or automatic. A constant voltage, direct current power source is most commonly used with GMAW, but constant current systems, as well as alternating current, can be used.

source-image: WeldNotes

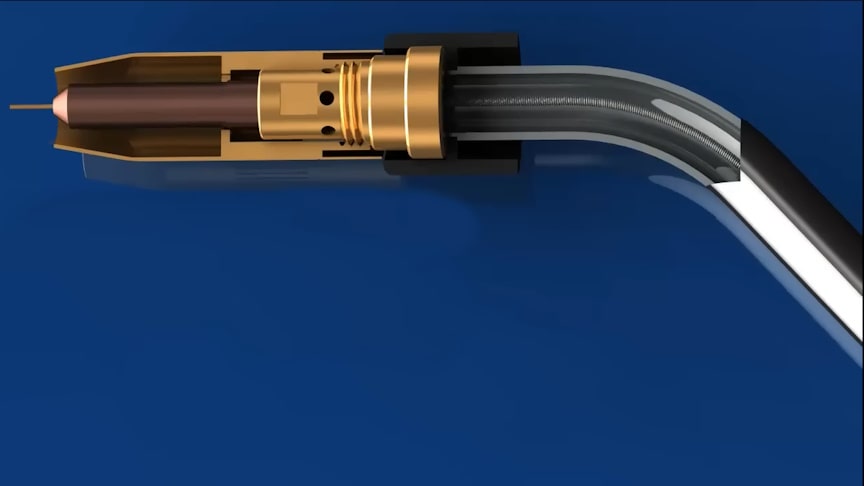

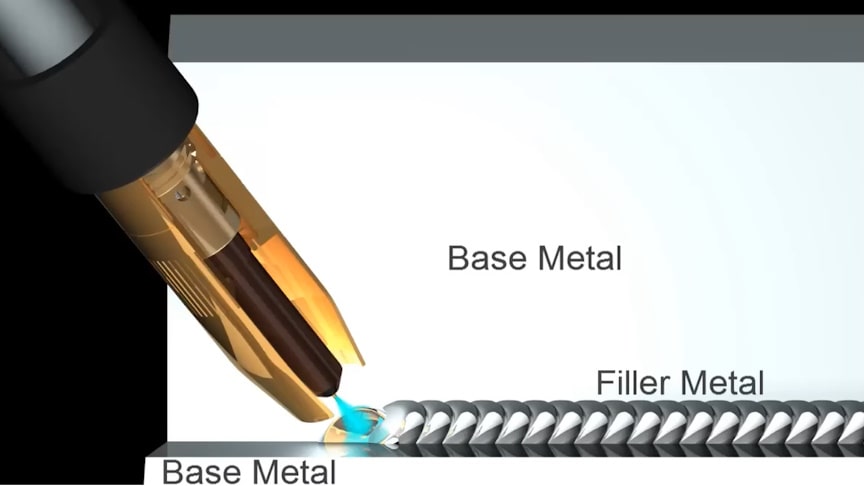

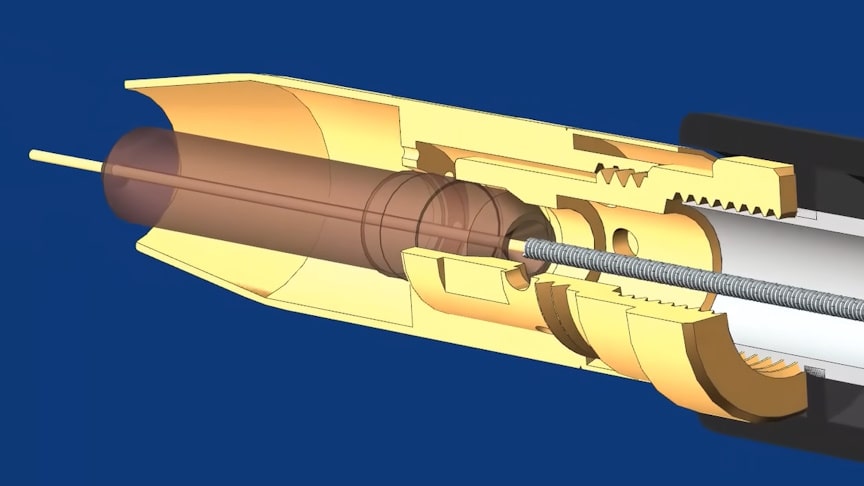

MIG welding uses a constant voltage power supply to create an electric arc that fuses the parent material with the wire that is continuously fed through the welding torch. At the same time, an inert gas is extracted from a supply tank and flows towards the gun, allowing the shielding gas to evenly protect the weld pool from impurities.

source-image: WeldNotes

The wire acts as both the filler material and the electrode, making the process fast and relatively easy to learn. In order to protect the arc from the reactive oxygen in the surroundings, a “shielding gas” also flows through the gas nozzle. This suppresses the oxygen during welding and therefore prevents oxidation on the arc and on the weld pool.

source-image: WeldNotes

MAG welding uses active gases such as pure CO2 or mixed gases (argon, CO2, O2) in various compositions. These are highly reactive. MIG welding, on the other hand, uses inert, i.e. unreactive, gases such as pure argon and helium or mixtures of argon and helium.

Advertisement

The process is suitable for welding materials such as aluminum, copper, magnesium and titanium. For most of its applications gas metal arc welding is a fairly simple welding process to learn requiring no more than a week or two to master basic welding technique.

Advertisement

This video is an introduction to the welding process known as MIG. MIG or (GMAW) is one of the most popular welding processes.

Even when welding is performed by well-trained operators weld quality can fluctuate since it depends on a number of external factors. All GMAW is dangerous, though perhaps less so than some other welding methods, such as shielded metal arc welding.